Industrial Automation - Robotics -Digital Twin - Generative AI

Smart, Connected, and Future-Ready Manufacturing Operation

We help your business transition from manual or outdated processes to fully automated, data-driven, and AI-powered operations.

Our Service help your Plant with integration between shop-floor automation (PLCs, sensors, robots) and enterprise systems (MES, ERP, PLM), ensuring real-time data flow for informed decision-making.

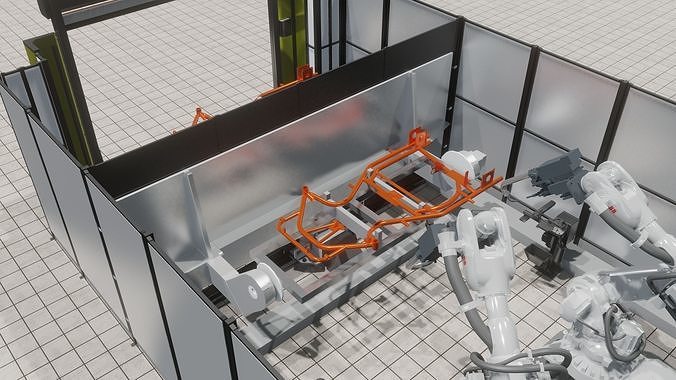

With virtual commissioning and robotic simulations, we eliminate uncertainties in automation projects before they go live, saving time and cost.

Who we are

Let’s build the future of manufacturing, together

We help you automate, connect, and optimize your operations —transforming industrial challenges into opportunities.

We help you bridge the gap between automation, robotics, and enterprise systems, ensuring seamless operations and real-time decision-making.

We focus on your business challenges, delivering tailored solutions that enhance efficiency, reduce downtime, and drive profitability.

From legacy system to AI-driven automation, we help you stay ahead in an evolving industrial landscape.

Digitalization thrives only with strong cybersecurity.

Without Cybersecurity, digitalized operations risk downtime, data breaches, and financial losses.

Robust Cybersecurity safeguards critical systems, protecting operations from cyberattacks and failures.

You have the power to build a smarter, more connected factory. We’re here to help you make it a reality.

Only you know how to steer your company toward future success, and we know how to power it with technology.

Enabling your Manufacturing with Cutting-Edge Technology

Industrial operations gain expert programming, development, and commissioning of Siemens PLC, HMI, and SCADA using TIA Portal. This enables precise control, real-time data insights, and enhanced efficiency, reducing downtime and optimizing overall production performance.

Using ABB RobotStudio for virtual commissioning, robotic systems are simulated, tested, and refined before deployment, minimizing downtime, mitigating risks, and ensuring seamless integration into production environments. Customer benefit from expert programming of ABB robots.

Improve energy efficiency through real-time monitoring, detailed consumption analysis, and shutdown performance tracking. Optimize energy usage per line or product, ensuring sustainability and cost savings while enhancing overall system performance with data-driven insights for better decision-making and resource management.

Maximize efficiency by tracking machine breakdowns, production rates, and scrap counts. Gain real-time insights into downtime causes, optimize performance, and reduce waste through seamless PLC and MES data integration for smarter decision-making.

Monitor critical station-related data, such as temperatures and welding quality, to ensure optimal process performance. Detect anomalies, prevent defects, and maintain high production standards through advanced data collection and real-time process insights.

Ensure accurate tracking and traceability of serialized data for JIT/JIS production. Improve quality control, reduce errors, and enhance production visibility with seamless integration between PLC systems and MES for reliable, real-time traceability.

How We help you

Implement Real-Time Production Bottleneck Detection

To detect and eliminate bottlenecks in real-time, we need a system that collects machine data, identifies slowdowns, and provides actionable insights to technicians and decision-makers.

PLC & Sensor Integration, Industrial Communication Protocols, Edge Devices or Gateways:

Real-Time Dashboards (HMI, Web, Mobile), Automated Alerts & Notifications, Augmented Reality (Optional):

Manufacturing Execution System (MES) or SCADA, Cloud or On-Premise Database, AI or Rule-Based Analytics Engine:

Automated Fault Diagnosis System, Knowledge Base & Digital Workflows, Integration with Maintenance Teams

(+27) 68 385 4070

You Get Performance Insights & Continuous Improvement

OEE (Overall Equipment Effectiveness) Monitoring: Tracks availability, performance, and quality losses over time.

Root Cause Analysis Tools: Helps engineers and managers identify persistent bottlenecks and improve processes.

Management Reports: Provides business leaders with data-backed insights to optimize production and labor utilization.

Trusted by world-class brands and organizations of all sizes

Testimonial

Client Feedback & Reviews

Your business demands efficiency, precision, and adaptability to stay ahead in a competitive market.